OPERATION

Embedded, hardened glass reflecting edge stud.

Retro-reflecting omnidirectional (360°) marking.

ADVANTAGES

Less maintenance required.

No energy consumption.

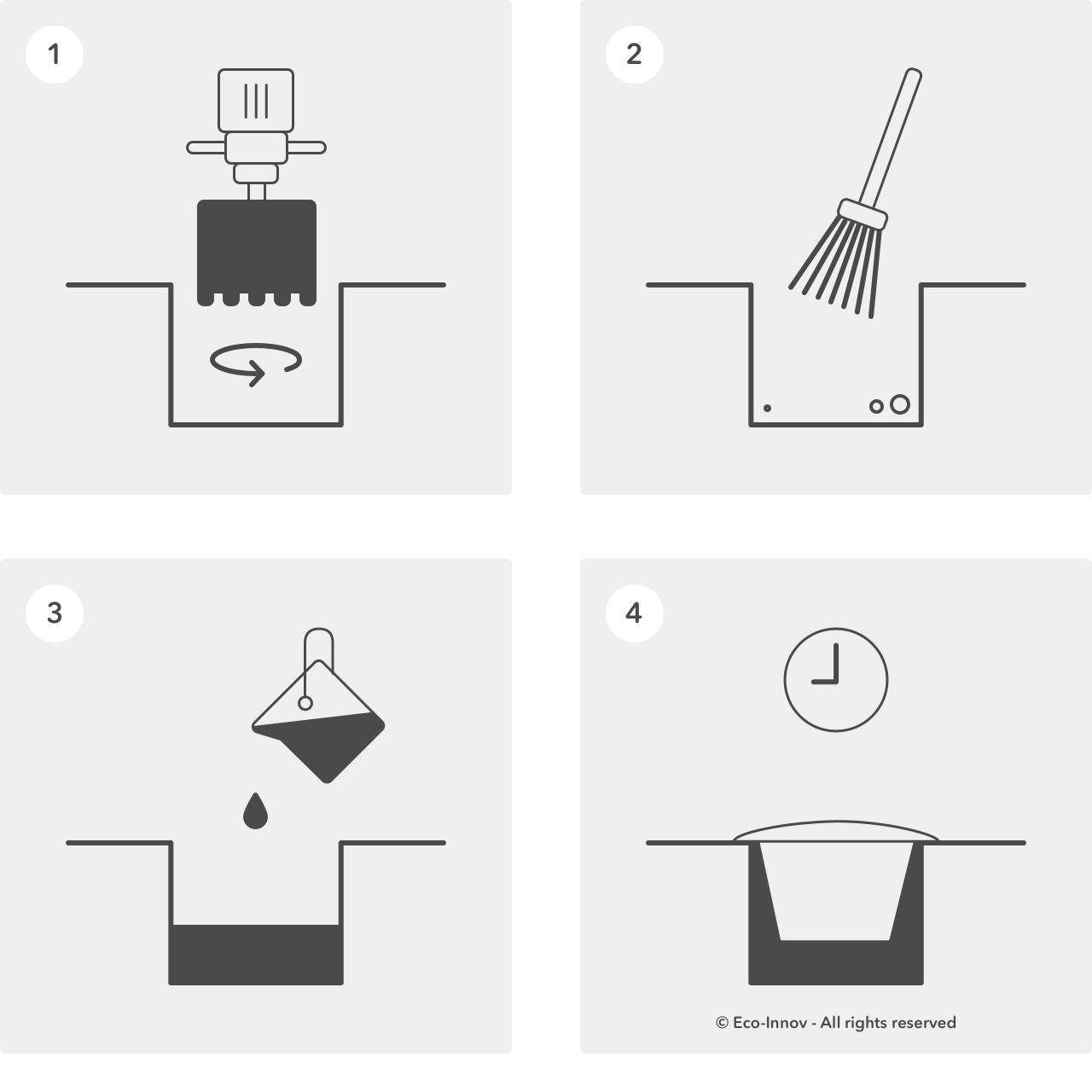

Quick and cheap to install.

Models with a rubber base can be installed in rainy weather as no epoxy adhesive is needed.

Glass is insensitive to static electricity (no risk of dust accumulating, which is not the case with plastic reflecting studs).

Glass is cleaned easily by rain, so no manual cleaning is required.

More durable than reflecting road studs made of aluminium or plastic.

Excellent mechanical resistance.

TECHNICAL CHARACTERISTICS

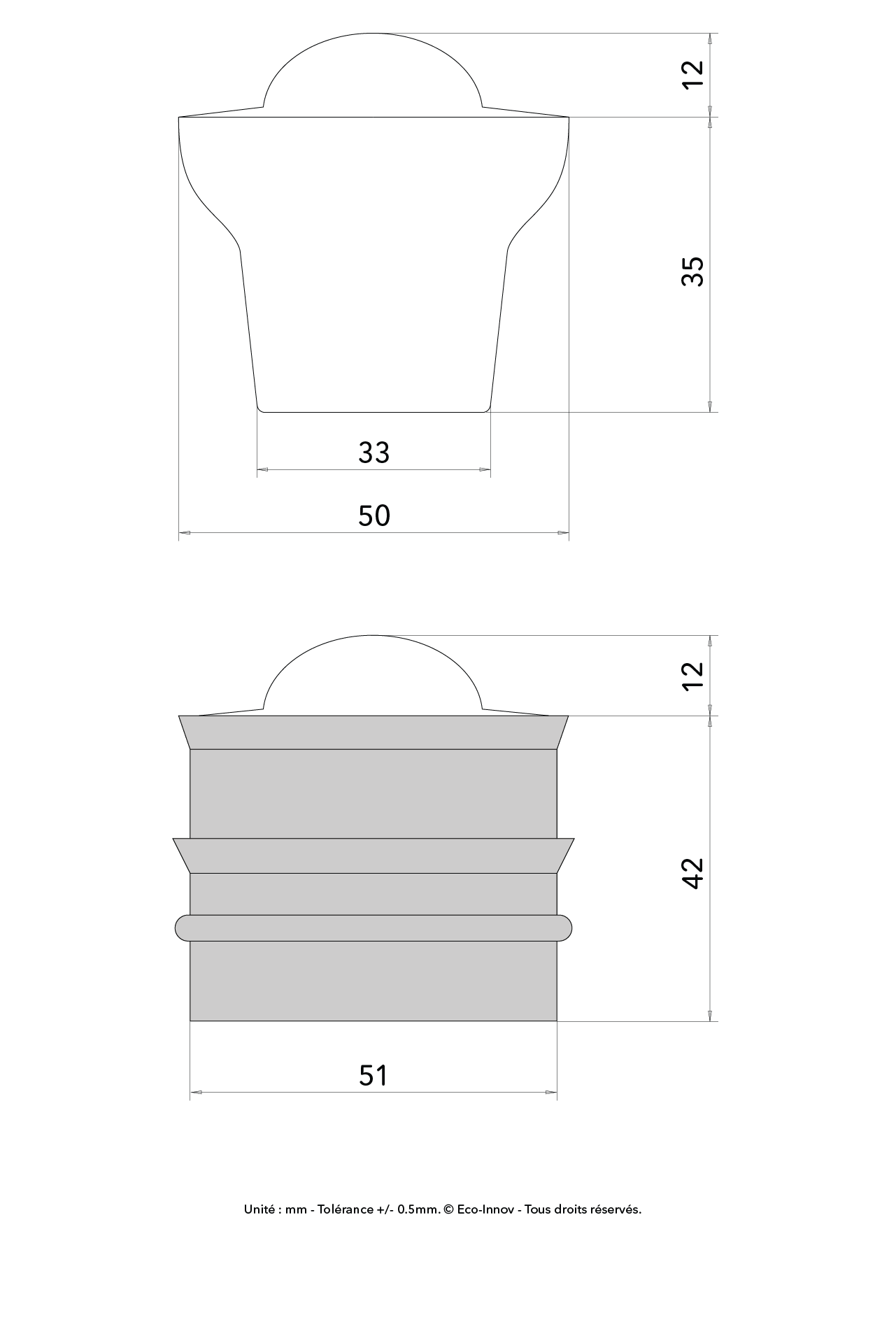

Dimensions and weight

Diameter of stud: 50 mm.

Weight: approx. 170 g.

Materials

Hardened glass.

Pressure resistance

More than 18 tonnes.

Available colours

White. Other colours on request.

Applications and conformity

Studs compliant with standard EN-1463-1 / EN-1463-2.