OPERATION

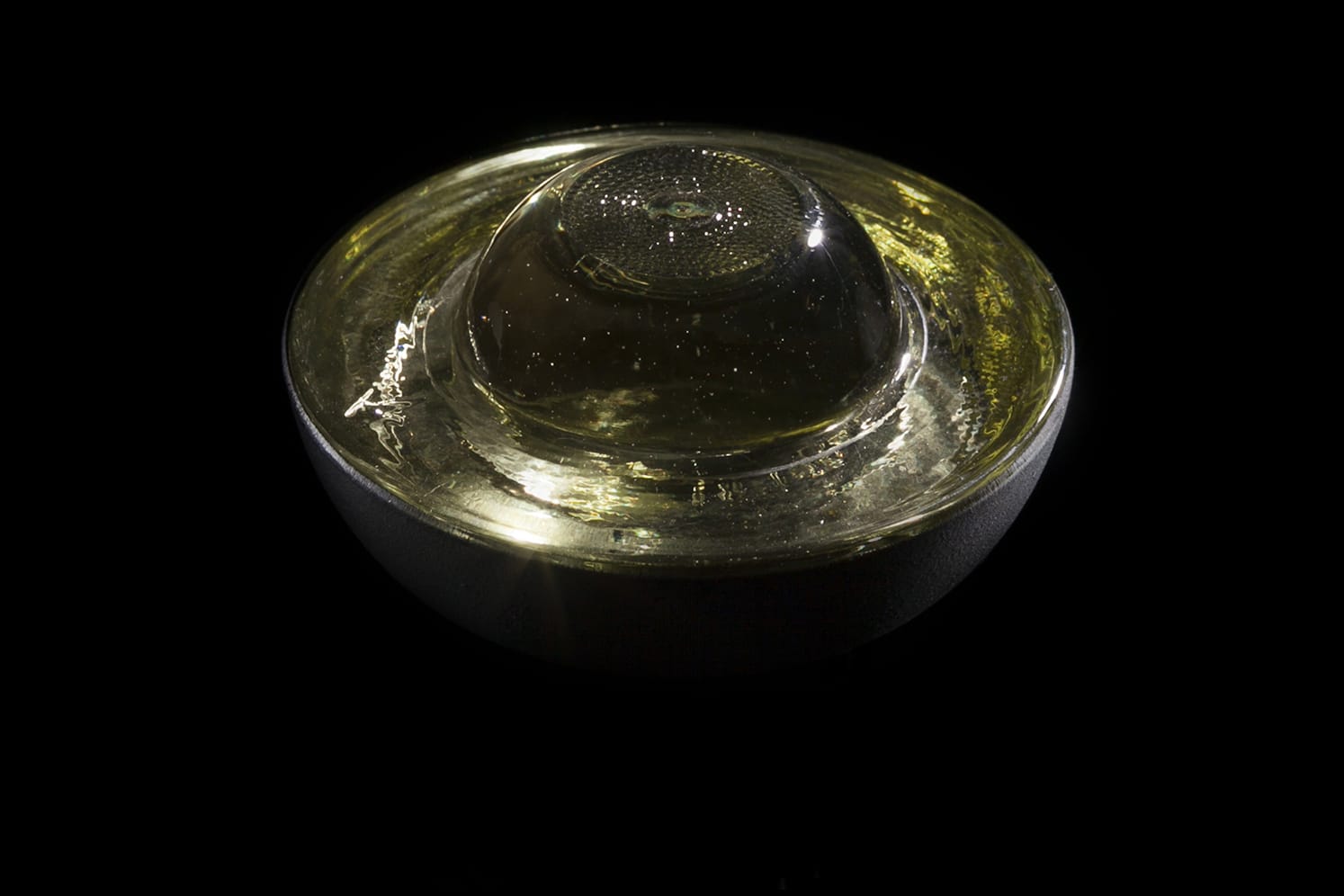

Embedded, hardened glass reflecting edge stud.

Retro-reflecting omnidirectional (360°) marking.

ADVANTAGES

Less maintenance required.

No energy consumption.

Quick and cheap to install.

Glass is insensitive to static electricity (no risk of dust accumulating, which is not the case with plastic reflecting studs).

Glass is cleaned easily by rain, so no manual cleaning is required.

Excellent stability of retro-reflecting properties over time.

More durable than reflecting road studs made of aluminium or plastic.

Excellent mechanical resistance.

TECHNICAL CHARACTERISTICS

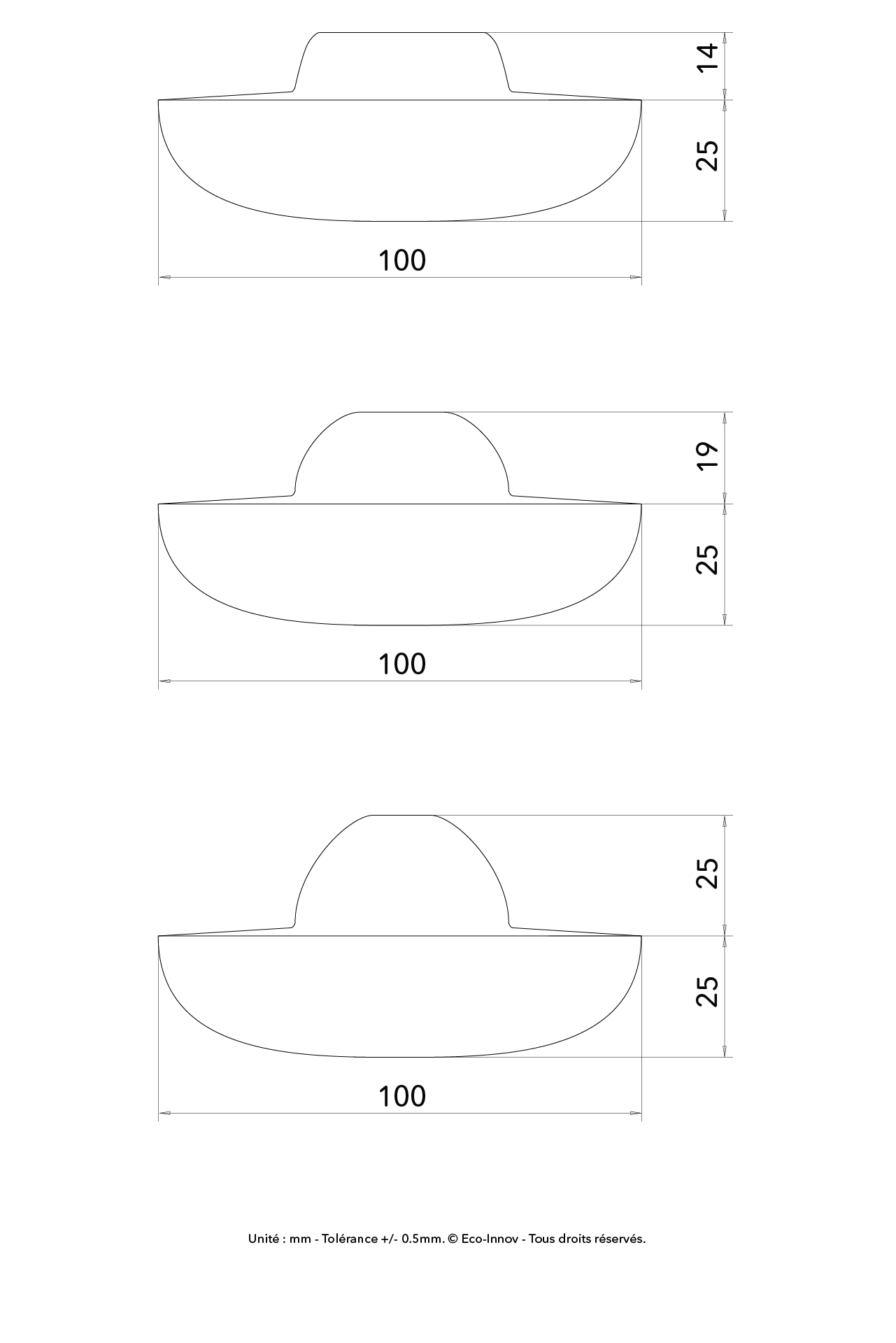

Dimensions and weight

Diameter: 100 mm

Height of dome 25 mm – Weight: approximately 540 g

Height of dome 19 mm – Weight: approximately 520 g

Height of dome 14 mm – Weight: approximately 480 g

Non-skid treatment on 14 mm and 19 mm domes.

Materials

Hardened glass

Pressure resistance

More than 40 tonnes

Available colours

White. Other colours on request.

Conformity

Our reflecting road studs with dome heights of 14 mm and 19 mm are compliant with standard EN-1463-1 / EN-1463-2.

Remark: it is advisable to install these reflecting studs in areas that pose no danger for users (cyclists, pedestrians, etc.).